end of arm tooling definition

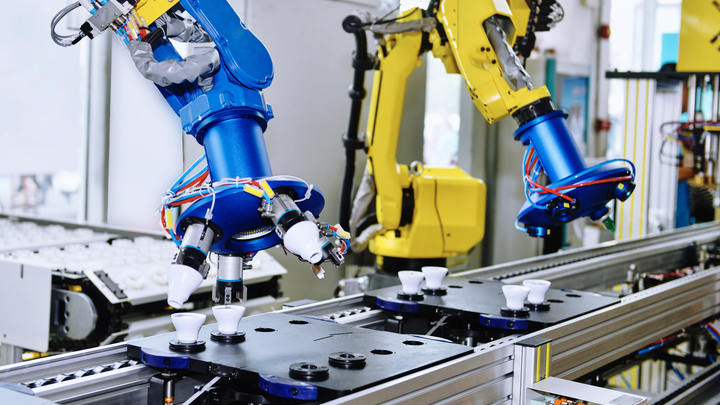

There are a wide variety from welders drivers grippers ladles riveter sprayers and more. Characteristics of End-Of-Arm Tooling 15.

What Is End Of Arm Tooling Eoat In A Robot Eoat Meaning

End of Arm Tooling or the end effector is the core of the robot tool in which the robot component communicates with the environment at the end of a robotic arm.

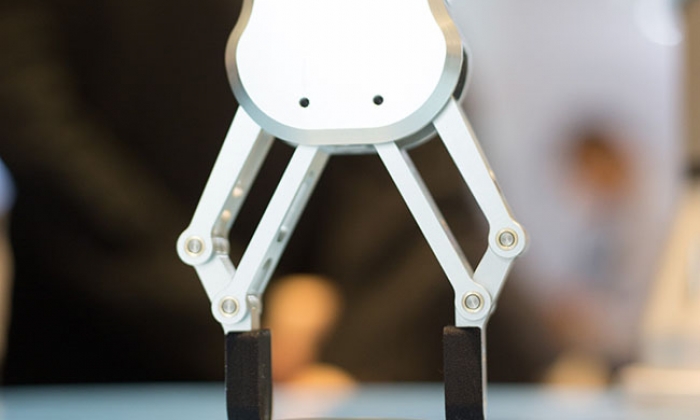

. Selecting the right gripper can make automation projects easier. Robots come from the manufacturer with a flat mounting area at the bottom of the arm called the wrist. Robot grippers are the physical interface between a robot arm and the work piece.

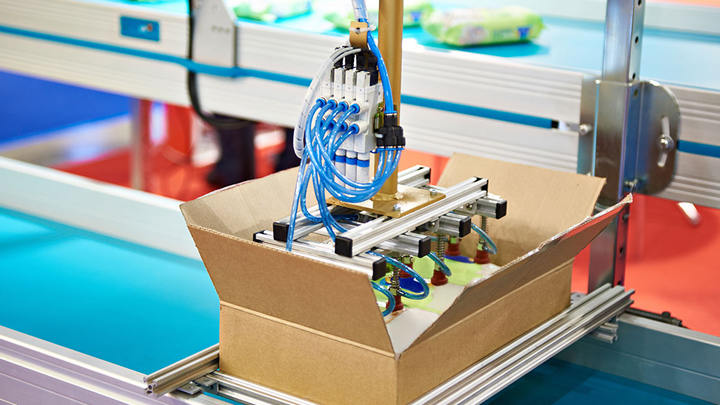

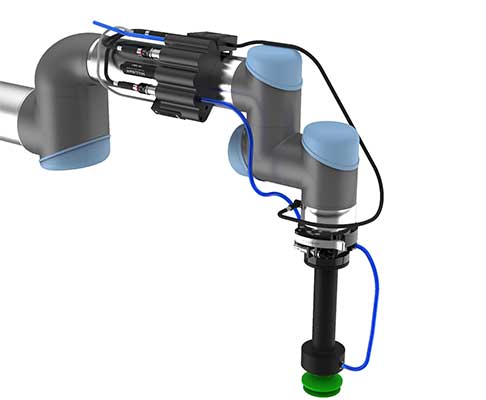

EOAT is used in a variety of industries including automotive and medical. These dependable stable systems allow for quick and easy tool changes reducing downtime caused by adjusting manual tool changers or manually removing and installing equipment. End-of Arm Tooling Makes the Difference When youre ready to automate your manufacturing processes one of the first questions youll face is whether to use traditional industrial robots or collaborative robots often called cobots.

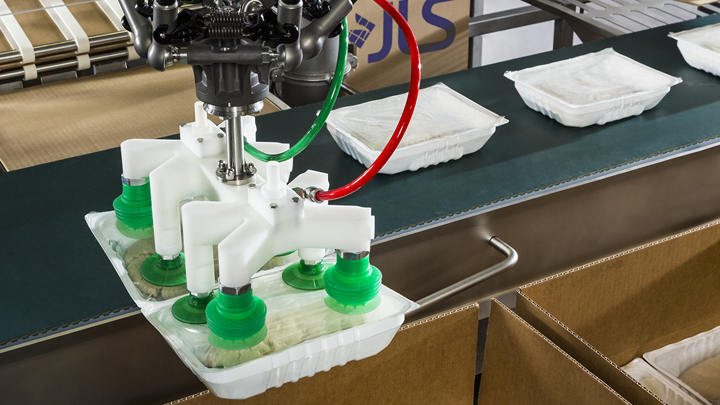

End of Arm Tooling EOAT refers to any device that is attached to the end of the robots arm that allows the robot to interact with parts in the environment and assists in the completion of a task. A lot of industrial automation especially in the manufacturing sectors deals with picking sorting packaging and assembly and the ability for a robot to grasp and hold onto objects is heavily important. An end-of-arm tool has many other names such as end effector claw gripper robot tool and others.

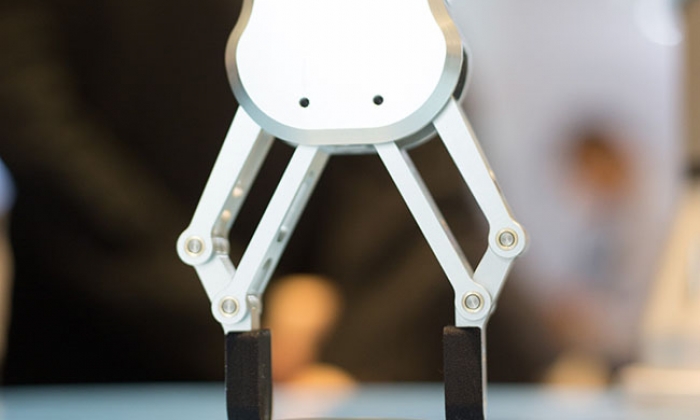

Precision mounting surfaces allow for the attachment of custom designed finger tooling. For example the welding torch on a robotic welding system. Simulating the incredible engineering of the human hand.

End of arm tooling definition Sunday March 27 2022 A robot gripper is an end-effector or sometimes called end-of-arm tooling that is used on industrial robots for material handling eg grasping holding lifting moving and controlling materials. The world of EOAT is full of innovative designs that have the same goal. If you have ever tapped into the subject of collaborative robotics then you have most certainly encountered the terms end of arm tooling or EoAT.

A hand is a good way to describe what an end of arm tool is. Learn vocabulary terms and more with flashcards games and other study tools. End of Arm Tooling simplifies the process of reconfiguring robotic end-effectors.

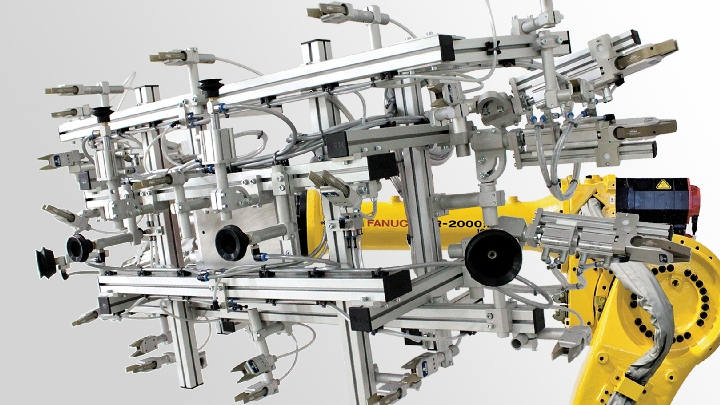

The end-of-arms tools are a key robot component and differ from one application to another. It refers to the equipment that interacts with parts and components typically at the end of a robotic arm. End of arm tooling may vary greatly between applications depending on the parts being handled and the actions the robot is required to perform.

Grippers or end of arm tooling devices enable the manipulation of an object. End of Arm Tooling - Glossary. End of arm tooling or EOAT is the field of robotic gripper technology.

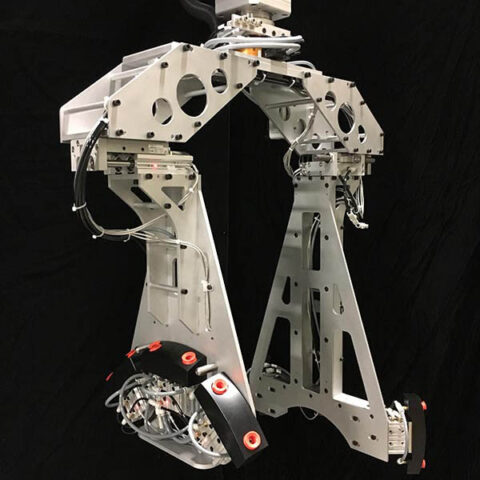

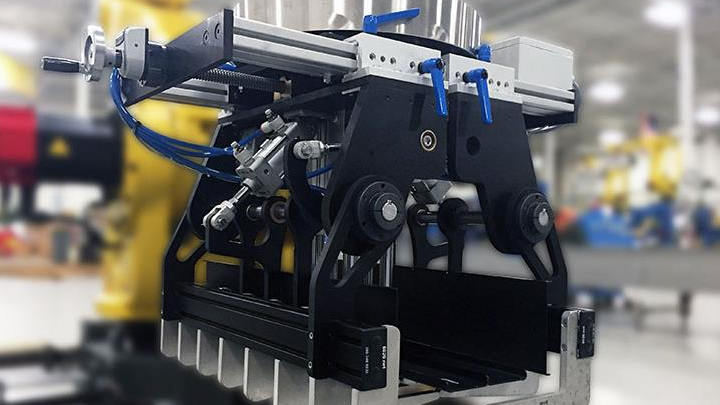

Our end of arm tooling EOAT grippers and robotic end effectors are custom designed and built for your specific application for increased speed and accuracy. Pin On Stealth Military Robo Tech Mech. It is the equipment linked with parts and components usually present at the end of a robotic armfor example the welding torch on a robotic welding system.

Robotic Automation Systems End of Arm Tooling EOAT provides. Basically an end effector is the business end of the robot Without an end effector most robots are practically useless. Simply put the object which connects the robot physically to the work being done is an end-of-arm tool.

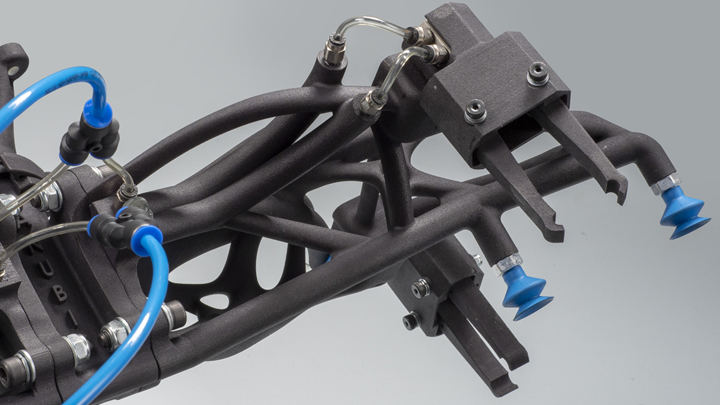

One could even say that there will be no automation advantages without at least one EoAT. Arc welding spot welding painting polishing grinding machining etc. Light tools allow the arm to move faster and more efficiently and conformal tooling maximizes the contact surface.

End Of Arm Tooling EOAT also known as effectors are the attachments of the robotic arm. Their robustly engineered construction and use of high quality components ensures long life and low maintenance. As you can see EoAT are crucial for.

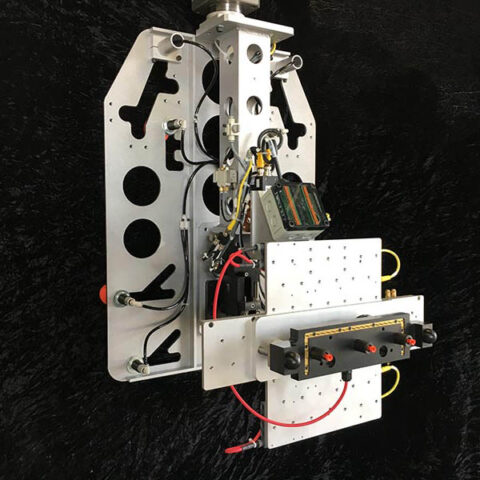

The wrist usually has tapped holes pneumatic air lines vacuum lines and electrical connections. End-of-arm tools come in many shapes and sizes depending on what work needs to be performed. End of arm tooling which is commonly known as end effectors are specific devices that are attached to the end of a robot arm which come in many shapes and forms.

End-of-arm tooling EOATthe hands at the end of industrial robot arms that enable industrial automation should be lightweight conformal to each unique part a robot manipulates and strong enough to move heavy parts. End of Arm Tooling EOAT could be gripers for clamping the objects or tools for manufacturing operations. Grippers Grippers are one of the more common end of arm tooling options given how they are used in automation sequences.

EoAT also known as end effectors - are crucial for unleashing the automation potential of collaborative robots. These devices are the key to allowing robots to do their jobs and interact with their environment. The end of arm acts as the hand of the robot allowing it to grab onto parts.

In this way the gripper itself becomes a measuring. Rock Abrasion End Effector on Mars Rover Spirit. A Special End Effector Designed By NASA.

What Factors Influence The Design Of A Gripper. Start studying Ch 5. This end-of-arm tooling EOAT is one of the most important parts of the robot.

End of arm tooling EOAT is a crucial aspect of robotic technology. They make it easier for your robot to interact with the environment and do the. A gripper is the mechanical or electrical End Of Arm Tooling EOAT device that enables the manipulation of an object.

An articulated robotic arm can be programmed to a particular location within its workspace but without some sort of end effector it has no way to perform any operation. As the name indicates this is a tool used at the end of a robotic arm. End of arm tooling EOAT is a fundamental feature of robotic technology.

Powered by electricity hydraulics pneumatics magnetics and vacuum these components are collectively known as the end of arm tooling or EOAT. Some grippers have built-in tool changers. Newer tool changers are designed to be lightweight as to not unnecessarily impact the payload of the robot arm.

A robotic tool changer facilitates easy and quick change of tools with just a few clicks you can eg switch your welding gun out with a spray gun. The term End Of Arm Tool EOAT may also be used.

End Of Arm Tooling Eoat By Robotic Automation Systems

Robotic End Of Arm Tooling Maximum Payload Considerations Youtube

Eoat Meaning Types Magnetic Gripper Manufacturer Hvr Mag

What Is End Of Arm Tooling Eoat In A Robot Eoat Meaning

Ultimate Guide To End Of Arm Tooling Eoat Dek

Ultimate Guide To End Of Arm Tooling Eoat Dek

End Of Arm Tooling Eoat By Robotic Automation Systems

Get A Grip End Of Arm Tooling Considerations For Collaborative Robots Manufacturing Automation

Ultimate Guide To End Of Arm Tooling Eoat Dek

What Is End Of Arm Tooling For Robots Onrobot

Ultimate Guide To End Of Arm Tooling Eoat Dek

What Is End Of Arm Tooling Eoat In A Robot Eoat Meaning

Ultimate Guide To End Of Arm Tooling Eoat Dek

Ultimate Guide To End Of Arm Tooling Eoat Dek

End Of Arm Tooling Robot End Effectors Millibar Robotics

8 Types Of End Of Arm Tooling Devices Grippers Keller Technology

Ultimate Guide To End Of Arm Tooling Eoat Dek

Robotworx Selecting End Of Arm Tooling

What Is An End Effector And Or End Of Arm Tool Eoat Ferrobotics